Compliant Pump Dispenser

How can compliant mechanisms be applied to improve the Green Design of conventional dispenser pumps?

I’m convinced that many of the solutions to our biggest problems can come as a result of revolution on a small scale, renovating the mundane architecture of our daily life rather than focusing solely on innovation that grabs headlines but has little practical value.

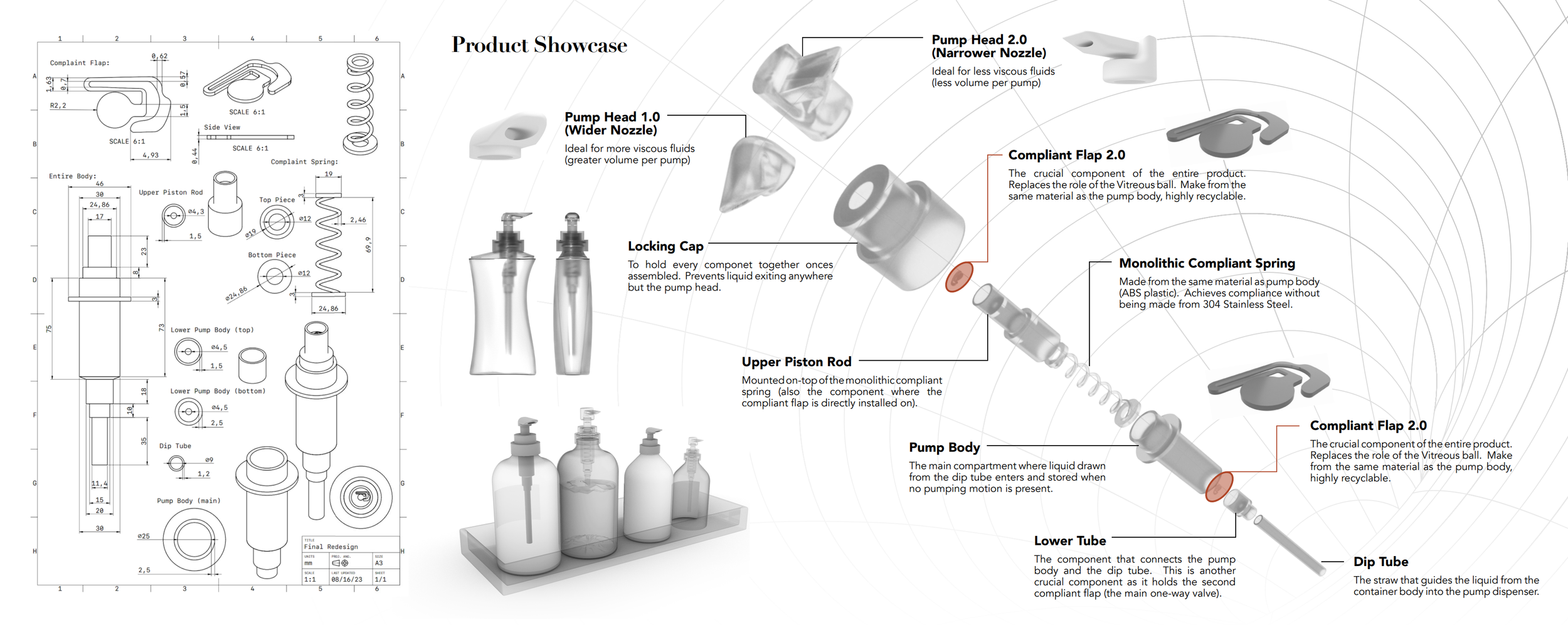

This philosophy of mine was responsible for my interest in what, in mechanical engineering, are called ‘compliant mechanisms’ - a mechanism that archives motion by the deflection of its material (like a tweezer). Recognizing their ubiquity in daily life, I wanted to create a line of compliant mechanisms that followed the principle of ‘Green Design’ - i.e., they are easy to manufacture, assemble, and recycle.

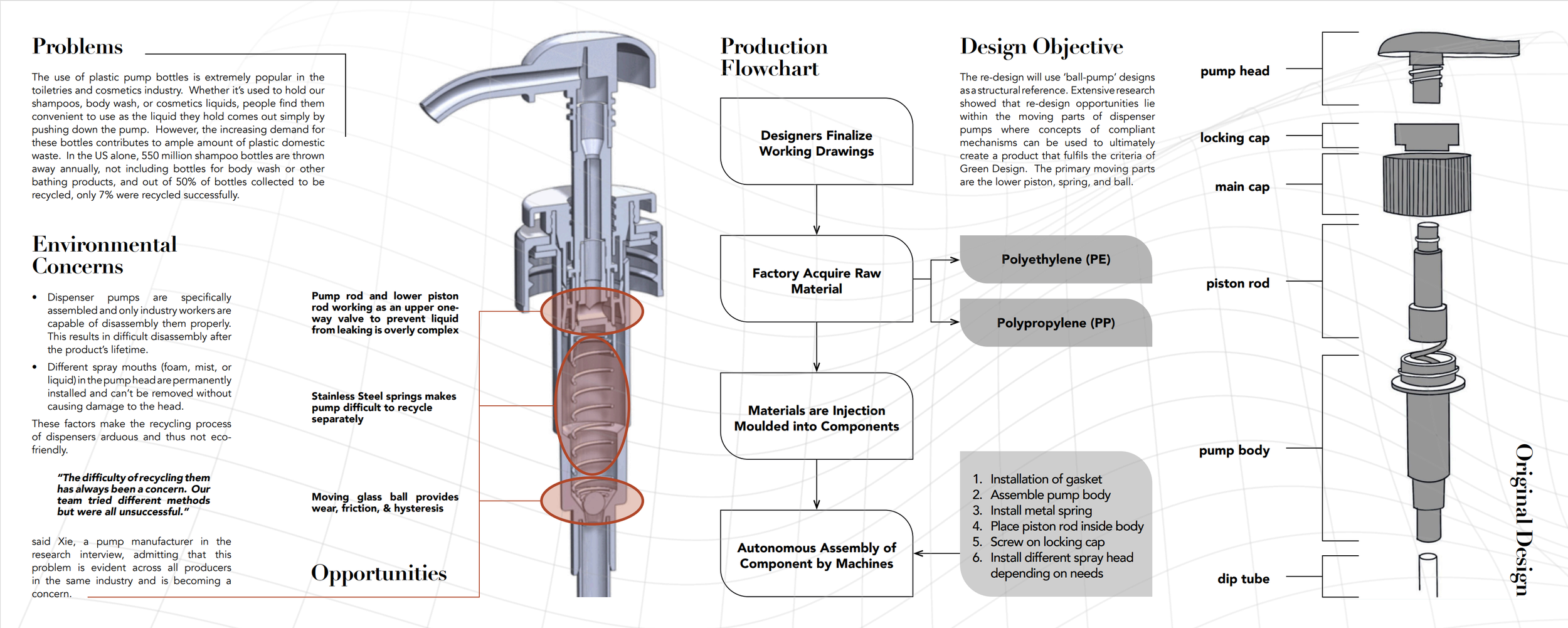

After some research, I became fixated on redesigning soap pump dispensers. They had too many components for what seemed like an easy job: “You pump down, and the liquid inside goes up.” Additionally, I learned they contribute heavily to plastic waste, which is exacerbated by the fact that they are made of many different materials. No wonder it couldn’t be recycled properly! I interviewed a medical expert who agreed with my diagnosis. Then, using CAD software, I designed a compliant structure of soap dispensers using one material, making it easier to recycle and reducing the components from nine to seven.